Only this weekend

Super Discount

Items on sale this week

Top picks this week. Up to 50% off the best selling products.

Glow PLA 3D Printer Filament 1.75mm,Fit Most FDM Printers

Rated 5.00 out of 5

2 Ratings

Ship within 24 hours

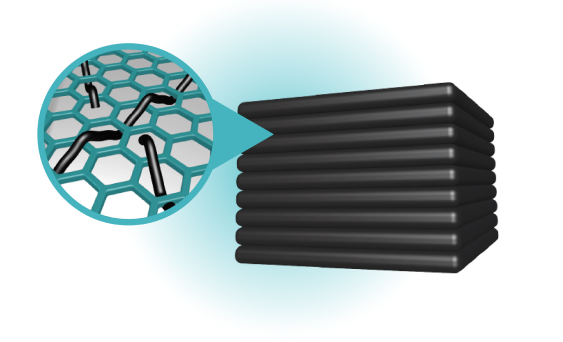

Super PLA+ 3D Printer Filament ,Toughness Enhanced PLA Plus

Rated 5.00 out of 5

5 Ratings

Ship within 24 hours

Oriental3d Aurora PLA 3D Printer Filament 1.75mm

Rated 5.00 out of 5

3 Ratings

Ship within 24 hours

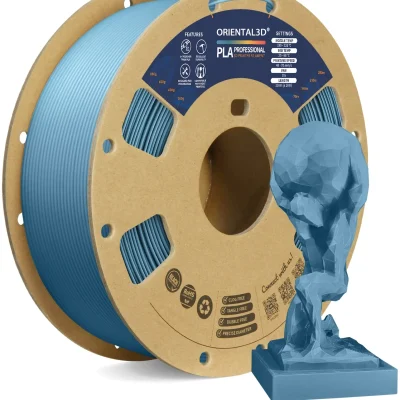

Oriental3d PLA Professional 3D Printer Filament 1.75mm

Rated 5.00 out of 5

2 Ratings

Ship within 24 hours

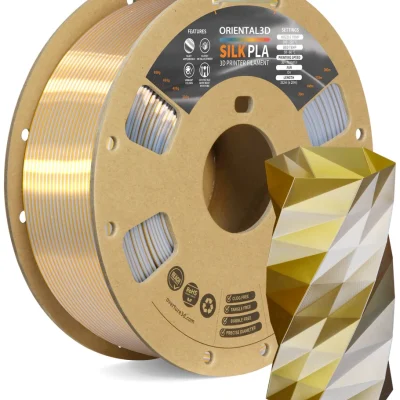

Silk PLA Dual Colors 3D Printer Filament 1.75mm 1kg

Rated 5.00 out of 5

1 Ratings

Ship within 24 hours

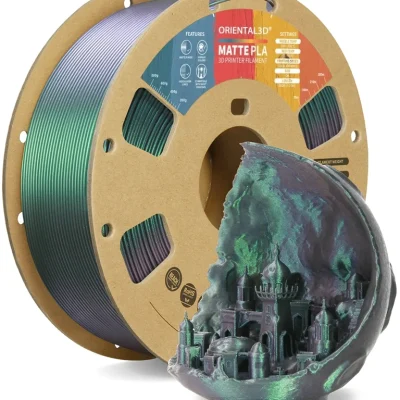

Matte Dual color PLA 3D printer filaments 1.75mm

Rated 5.00 out of 5

3 Ratings

Ship within 24 hours